Pikus Rockwork

Solutions

Browse our PikusPrinted™ modular rockwork

Rockwork Made Simple.

Your Path to Success

Site Elevation Plans

LiDAR of Clay Model

100% 3D Assets

Accepted 3D File Types:

3DM

STP

STEP

OBJ

STL

ROCKWORK FAQS

READY FOR SOMETHING BETTER?

3D Printing

Chip & Tab

VS.

SPEED

Chip & Tab is vulnerable to weather and on-site delays.

3DPG is printed in a climate-controlled facility and arrives ready to be installed. With Pikus, your lead times are dramatically cut short. 3DPG pieces can be printed and shipped within just a few weeks, leading to faster project completion than ever before.

SLEEK

Chip & Tab is pixelated fabrication

3DPG is tesselated fabrication.

SAVINGS

The cost of chip & tab fabrication and installation is primarily driven by local labor and installation times are longer, resulting in increased costs.

PikusPrinted rockwork dramatically reduce is on site, fabrication, enabling owners to open soon or increasing potential revenue.

SAFETY

Chip and tab utilizes high-risk labor-intensive fabrication. This may involve cutting, welding, and projectiles amongst other on-site hazards.

Fabrication without shotcrete reduces the risk of projectiles while the pre-fabricated panels reduce the working height at all stages of the project. 3DPG reduces the need for cutting and welding while providing a light-weight and sturdy structure.

SUSTAINABILITY

Chip and tab construction relies on a steady supply of non-renewable resources, including steel and concrete. With old fabrication methods, the huge amount of materials needed to fabricate rockwork greatly reduces project sustainability.

By eliminating half of the material and leveraging the use of recycled water bottles in our product, we drive a much more total sustainable solution.

STRENGTH

Chip and tab is 2x the weight of 3DPG rockwork and as much as 6” thick, making it heavy. In addition, the use of lath introduces a likely failure point.

3D poly grout is typically 2 to 3 inches thick resulting in half the weight of shotcrete and the elimination of lath. Grout is not only stronger but less prone to failure.

Rockwork Attatchments

Easily connect 3DPG Rockwork Pieces

-

Pikus™ 3DPG rockwork can be painlessly assembled with several different types of connections, including Z-clips, split tab clips, and U-clips. Each of these connections can be attached to a wall or support behind your rockwork to lock your printed pieces into place. It is recommended that the rockwork pieces be assembled and attached together before being finished with a rockwork coating.

-

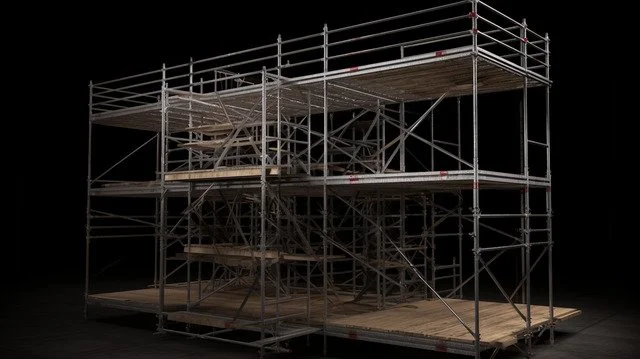

Complex or free-standing rockwork can be supported with steel rods and traditional rockwork stands. These supports can be easily hidden within the 3D-printed structure. The steel rods can be combined with other internal support systems to ensure a secure foundation for your statement rockwork pieces. For more information on the assembly of your 3DPG rockwork, please contact create@pikus3d.com with all of your questions.

View the 3D model