FILL & GO™ FORMS

Speedy and safe structural concrete solutions.

Fill & Go Form Installation & Safety

Learn step by step the simple process of installing Fill & Go™ forms on your job site. This insightful article will cover column staging, rigging and setting, connecting and plumbing, and the filling process. For a general overview, please reference the Fill & Go™ data sheet below.

A Speedy Process

Column Design Options

Geometric

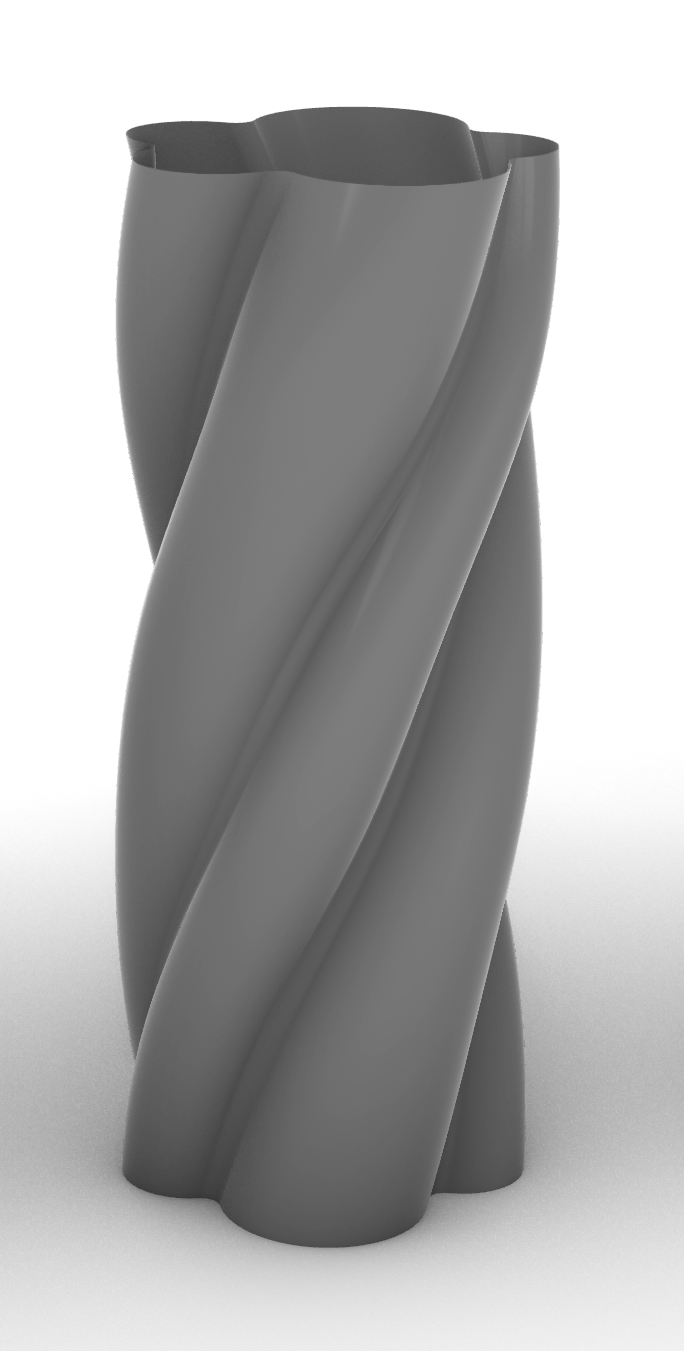

Flow Twist

Split Twist

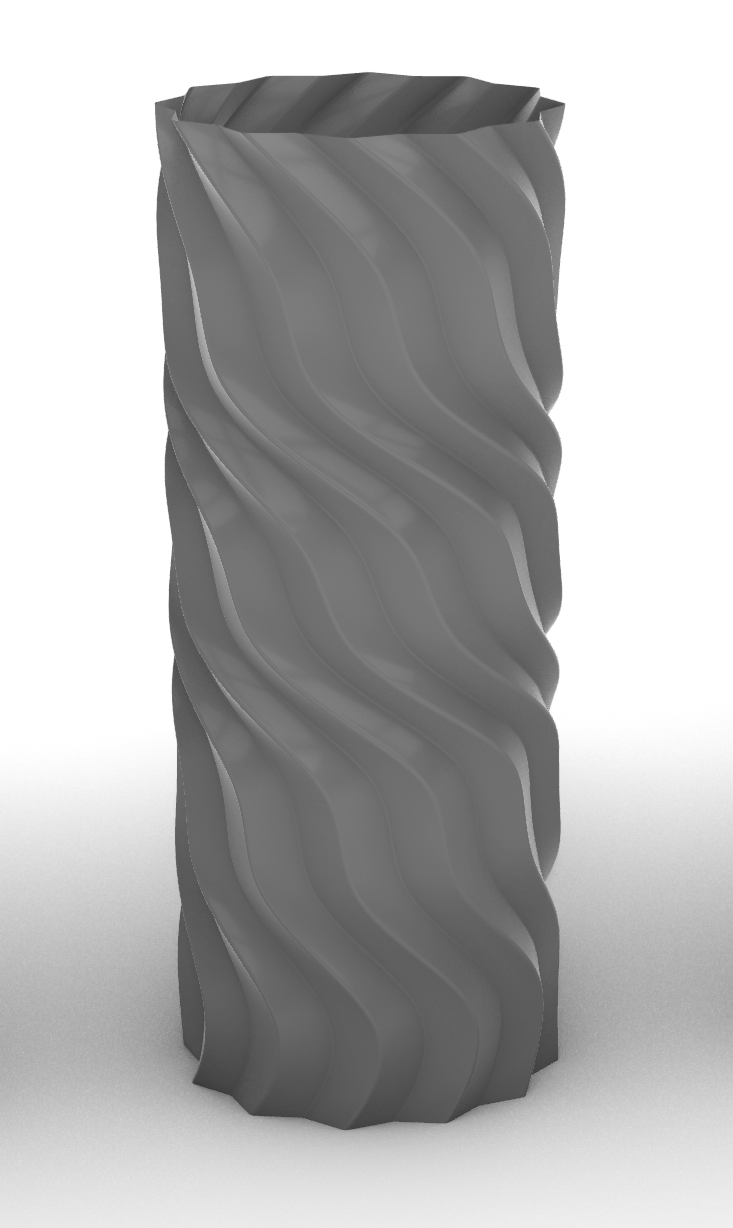

Wave

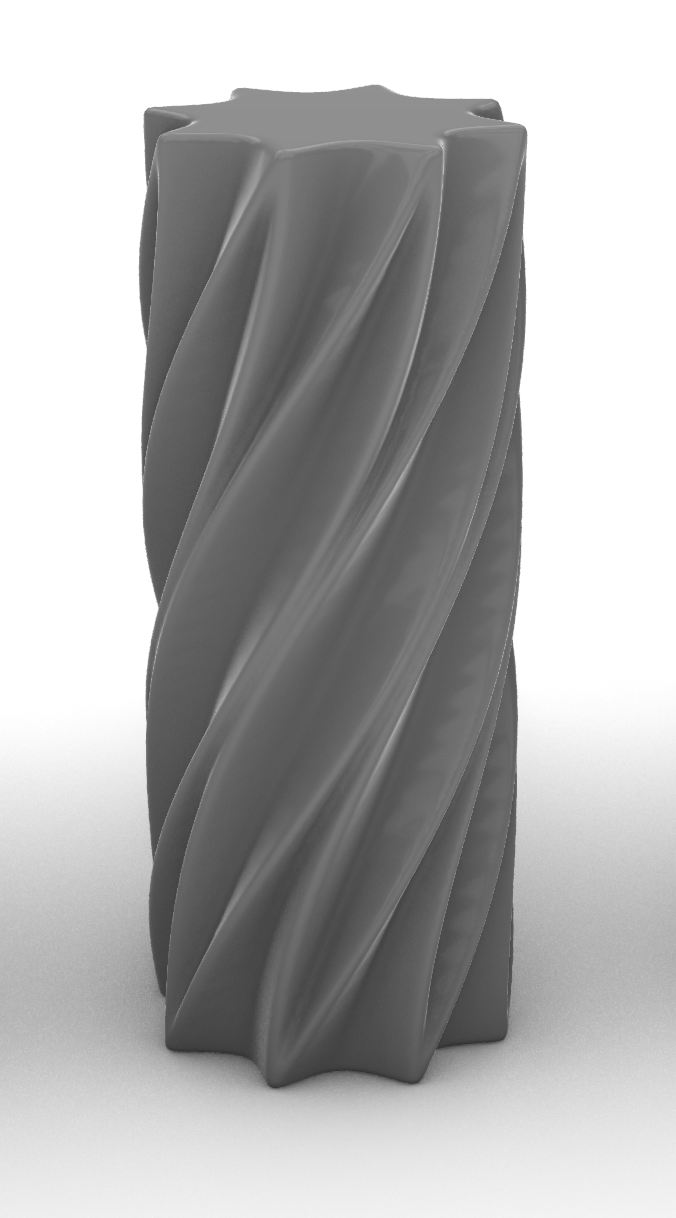

Chunky Twist

Classic Twist

Paper

Carved

We are launching the Fill & Go™ system through Pikus Certified Installers who have met safety and training standards. If you are interested in being trained as a Pikus Certified Installer, please contact us at create@pikus3d.com to arrange a training session for your team. Following training, Fill & Go formwork will be available for purchase. Open training sessions are scheduled for quarter 3 of 2024, aligning with the release of columns for public purchase.

Availability

STANDARD FEATURES

Fill & Go™ forms arrive with factory-installed plumb points. The PlumbPoint™ will be attached to the top section of the column and allows to be quickly plumbed with turnbuckle. DO NOT overtighten. Consult Pikus for torque settings.

PIKUS PLUMBPOINTS™

Fill & Go™ forms arrive with factory-installed protective wrap. This ensures that your Class-A concrete architectural finish is protected from concrete splash, abrasions, and dirt until opening day! The wrap is simply removed with scissors. DO NOT remove the PikusProtect™ wrap until after all trades are complete with their work on the job site. Doing so voids the warranty.

PIKUSPROTECT™ WRAP

RigReady™ forms are available with factory-integrated choke straps, so that your column sections are stackable from the pallet. No hunting around the job site for straps. Prints arrive RigReady™ to save you time. Site conditions may require other methods to set.

PIKUS PICKPOINTS

Optional Features

Safe Construction

Reducing the safety risks of traditional concrete.

-

Fill & Go columns significantly reduce installation time by reducing the number of sections to set and eliminating form removal. Fill & Go forms result in an architectural finish without hazardous silica dust from rub and patch. This column system reduces the amount of handling necessary to complete a job.

-

Sections are rigged from their pallets overtop rebar cages. Once factory-installed plumb points are braced, they are ready to be filled & consolidated. No form oils. No Rub & Patch. Just Fill & Go!