SAVING YOUR SCHEDULE

How 3DCP reduces risk of schedule overruns

YOUR TIME IS VALUABLE

Schedule overruns have become synonymous with construction. With rising inflation, the burden of running over schedule becomes a real pain for developers who forego income streams while contractors complete their tasks. Pikus 3D, a pioneer in 3D printed concrete products, has launched several product solutions that shave time from your production schedule, most specifically from the time that is consumed by cast-in-place concrete. In this post, we are highlighting two of these solutions: pier elimination and footer integration.

3D-PRINTING IS

SPEEDY

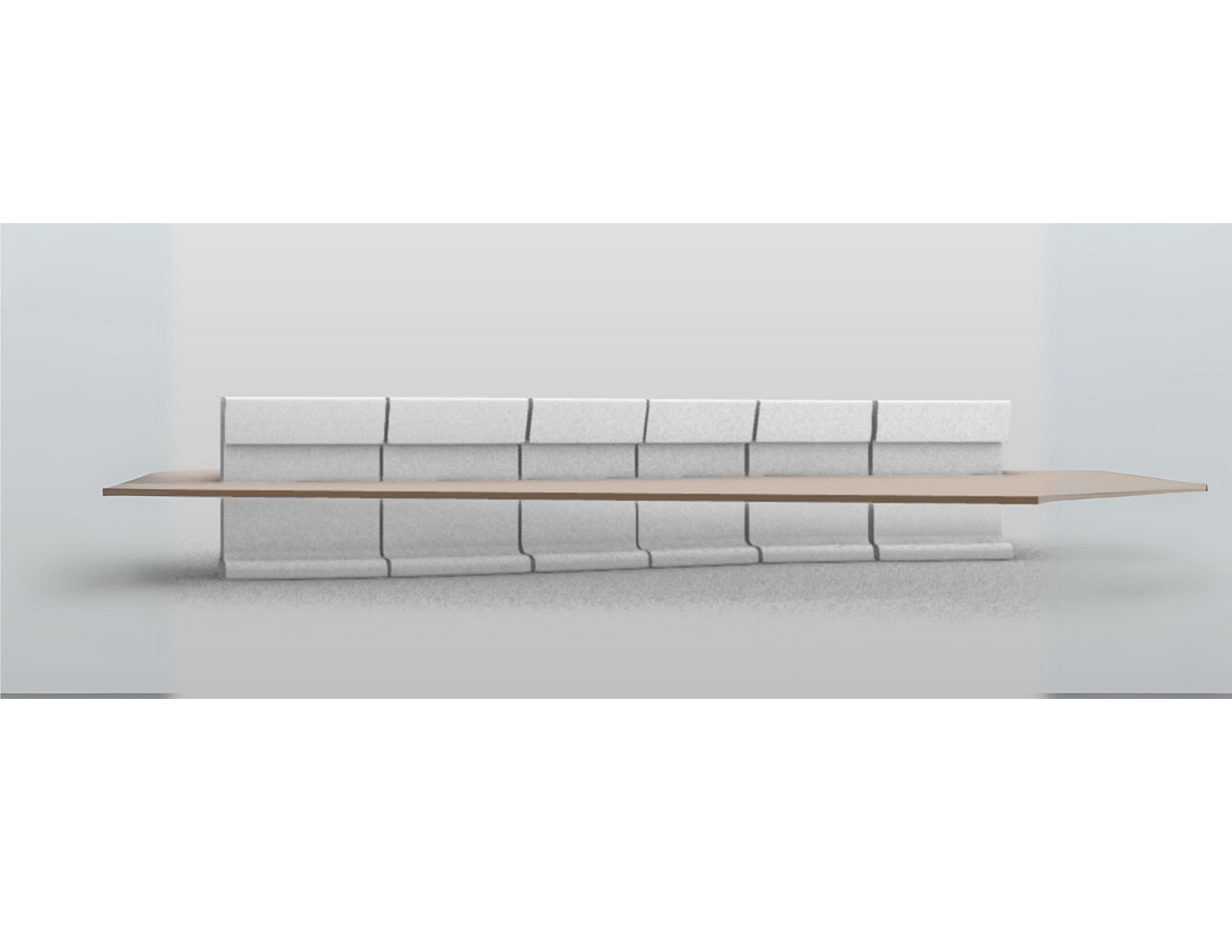

Kennedy Center bench with deleted stem wall

This is exactly what Pikus did for the City of Orlando at Lake Eola. Chris Rice of Borrelli and Partners worked with Pikus to Design a highly efficient seating element that had beauty but felt organic. By utilizing 3D concrete printing (3DCP), these elements were 80% lighter than an equivalent precast option. Pikus calls this seating object a Bolide, and it looks like a large pebble. These Bolides are efficiently designed and manufactured in the USA, where the comparable precast item would have several months of lead time, this product merely takes weeks. Also, a competing precast item would be solid concrete and weigh 3,000 pounds! The 3DCP product is merely 550 pounds. As a result, piers were eliminated from the plan. No installer was needed to bid them or waste time on waiting for them to cure. This saved time and expense from the construction schedule. And, this lightweight 3DCP design enabled the seating objects to be moved with straps instead of a crane, further saving time on the schedule.

Eliminating steps from your install plan is one of the best ways to save time. Take for instance removing or reducing piers and footers. These Geotechnical elements are necessary when your objects are heavy and may subside or, worse, differentially settle into the soil without support. Yet, piers and footers may be unnecessary when the product is lightweight. This is made possible when your object is designed efficiently, not over-engineered, resulting in substantial weight savings.

PIER ELIMINATION

Planter with Integrated Footer

Bolides at Lake Eola in Orlando

FOOTER INTEGRATION

Another way to save time on your installation schedule is to combine steps. Pikus does this by integrating construction complexities into a single product, reducing steps and trades. In the photo above, you can see how Pikus designed an integrated footer within the planter. By doing so, we eliminated the need for bar busters, irrigation installers, and finishers to be involved in this planter. Baker Concrete’s Ben Goodin(the installer of these planters) said “This design feature shaved approximately 4 weeks off our project schedule”.

As a project executive who is incentivized to keep your project on schedule, consider how you can use 3DCP PikusPrinted™ products to eliminate piers or integrate footers and save weeks on your next project program!

Bench with integrated footers