BEST PRACTICES FOR 3DPG

An acknowledgement of limitations and how to get around those limitations.

The Limitations of 3DPG

Like any material, 3DPG is not without its limitations. Though robotic and material advancements are being made every day to overcome these minor limitations, there are currently boundaries that are put into place to consider a piece as “printable”. The list is short but it is important to keep the a few things in mind when designing a 3DPG statement piece.

The most crucial limitation of current 3DPG technology is the angle of the print. Though this may vary depending on the size of your design, the angle that our Pikus designers suggest as the maximum angle is 35° though specific prints can achieve 45° and even become fully enclosed with the right design tweaks. If you need any more guidance on what is achievable for your project, dont hesitate to contact us. We will be happy to review your design with you.

The only other major limitation is the size of the print. Though our printer can scale up to 13’x12’x15’ it is extremely abnormal for pieces to be printed this large. This is due to the restraints of shipping and handling of the prints and the added costs associated with that. To keep our pieces mobile and stable, we reccommend not exceeding a size of 6’x6’x12’ so that your piece is easily shipped and handled.

WE DESIGN

AROUND OUR

LIMITS FOR

QUALITY PRINTS

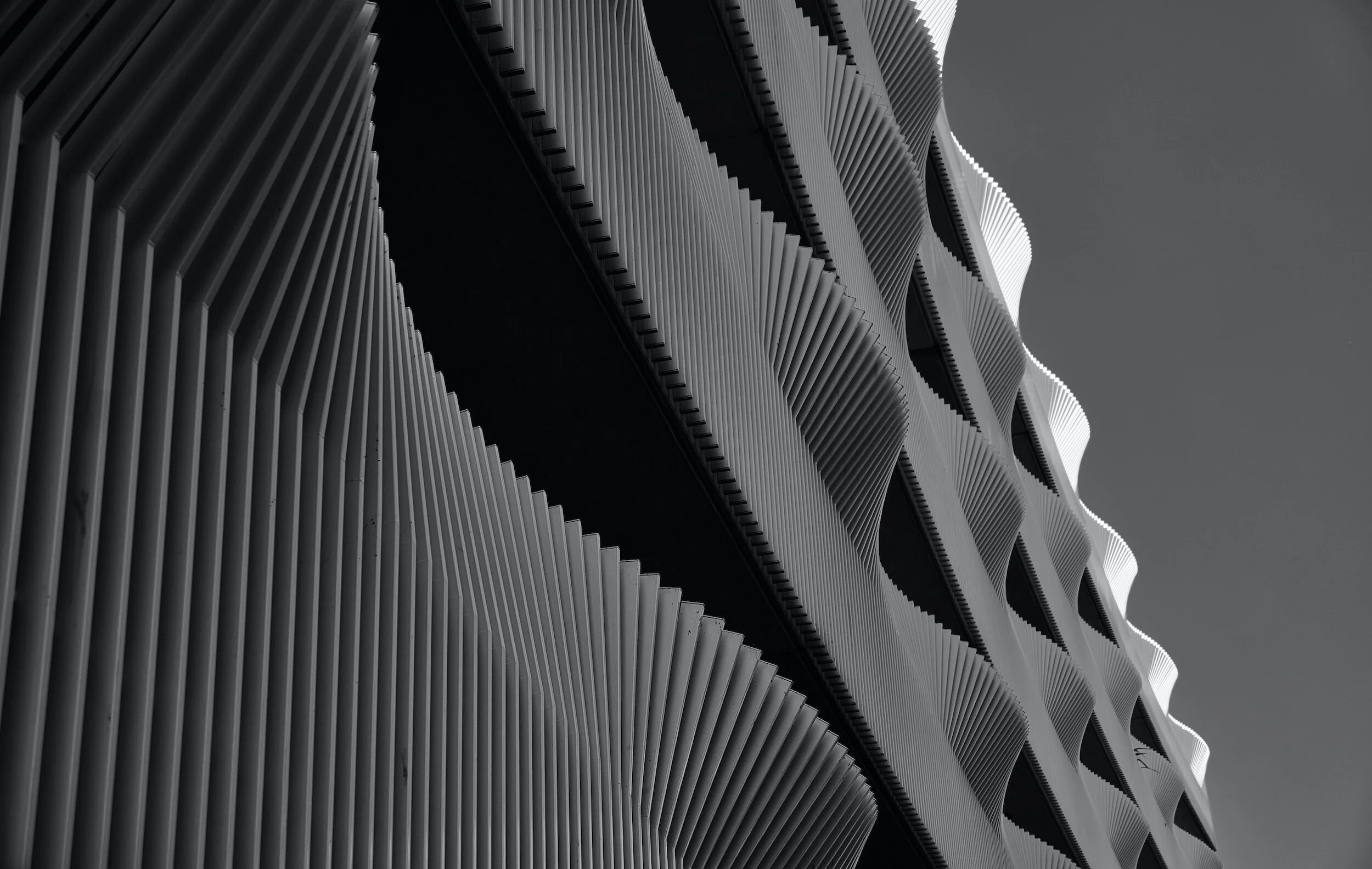

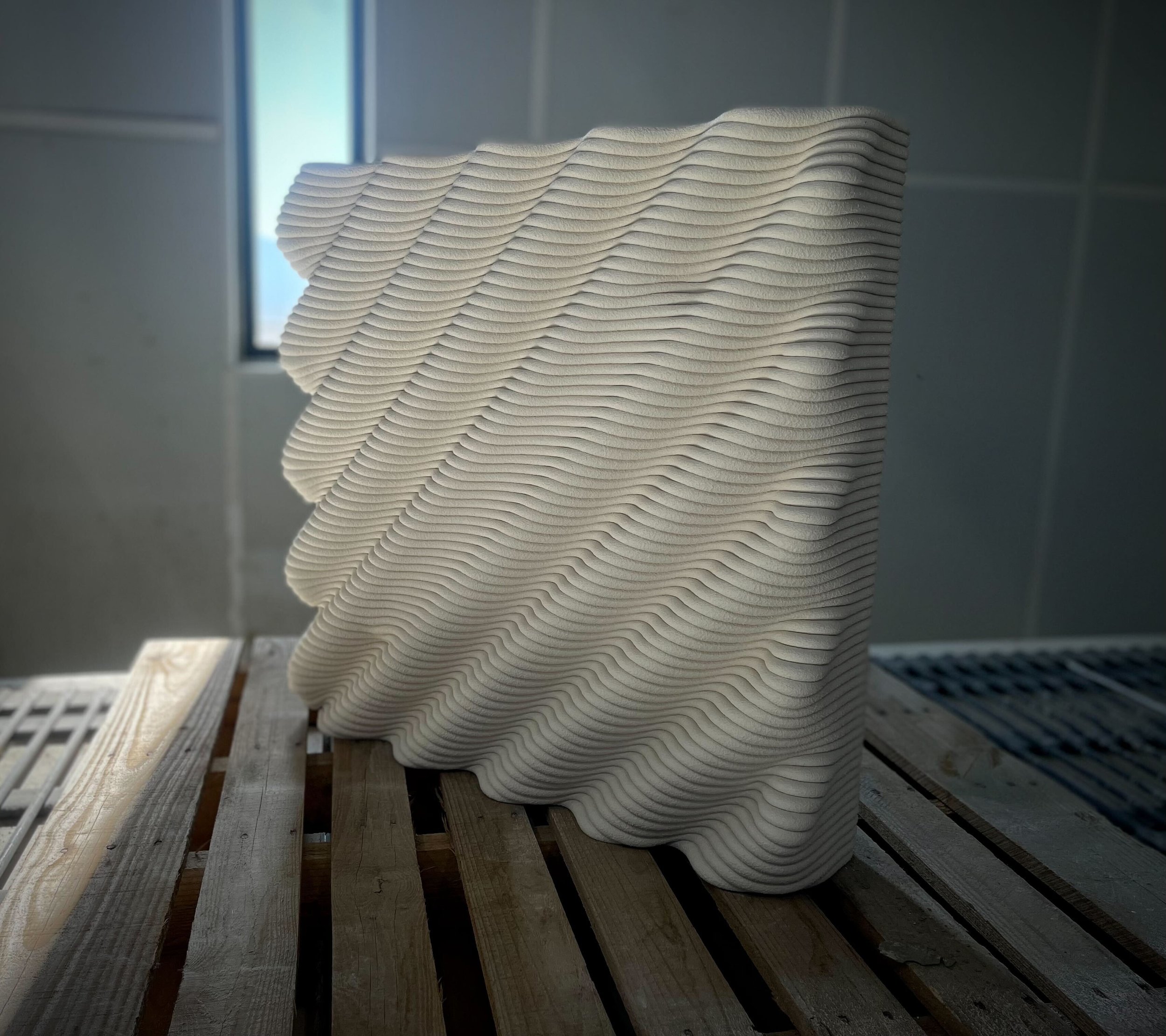

There are a few less noticeable limitations of 3DPG. Our 3K printer creates a smoother print line with a continuous path, which means that sharp corners and sudden changes in direction are quite difficult to achieve. The corners will usually end up slightly rounded with a smooth print line around the edges. The more organic the print is, the easier it is to print generally.

Bypassing Limitations

Although there are some obvious limits to 3DPG, there are also many different ways to bypass them. There are two primary ways of bypassing any print limitation on angles and size: changing the orientation of the print and cutting the print into multiple pieces.

If there is a specific angle that you would like to be printed, but it is larger than 35°, then it may be time to look at the piece from a different direction! In many instances, a piece can be printed on its side or even upside down to create a more realistic print path for Pikus systems. By looking at the piece from a different angle, architects and designers are able to minimize the amount of adjustments that need to be made to their creations to make them printable.

There are many uses for 3DPG, and though we must acknowledge the limits of such a product we can also devise ways around the same limitations. Our designers at Pikus have become very familiar with all of the workarounds and changes that must be made to create a “printable” product. Each team member at Pikus wants to help bring your dream to life, and we will do everything in our power to make sure that the pieces you order are exactly as, if not better than, you imagined.

The other way to get around print angles and size constraints is to slice the print up into multiple pieces. This is especially useful when it comes to creating statement walls and large water features, as the size of such projects can sometimes get in the way of reasonable printing standards. By utilizing multiple pieces and cold-joint connections, we are able to minimize shipping costs and achieve unique prints that were never previously thought possible.