A SOLID FINISH

Navigating the future of rockwork with 3DPG

A Simpler Future

When you enter the gates of your favorite theme park, it is more than likely that you are surrounded by more than one massive rockwork installation. These stunning pieces truly bring an environment to life and transport guests into a new location. These feats of entertainment often seem to be magically dropped into place, but to tell the truth the current amount of work that goes into creating these structures is astronomical.

Rockwork is created using a “chip and tab” system. The bulky process includes steel supports, wire backing, layers of foam and carve coating to finish it off. It can be difficult to repair and maintain. This system is quickly becoming outdated with the technological advancements but it is hard to determine the best materials on the market to create rockwork.

That is where 3D printing comes into play. 3D printing graciously allows designers to take control of their own designs and hold the rockwork installation to a higher standard. There are so many benefits to using 3DPG especially. The material is stable, allowing for limited use of steel supports in favor of clip-in systems. 3DPG works with integrated color, so there is no need to worry if the rocks chip because the layer underneath matches. From sustainability to installation to artistic freedom, the benefits of 3DPG rockwork are taking the industry by storm.

BEAUTIFUL

ROCKWORK

IN 3 SIMPLE

STEPS

The world of rock creation is entering a simpler future. Now that the designs can be printed in a single day and carve-coated within 7 weeks, it no longer makes sense to use the labor-intensive chip and tab method. Pikus aims to provide creative freedom to the designers who request these beautiful statement pieces, no matter the size or location. 3DPG has opened many doors in this industry for larger creations than ever before.

Theory In Practice

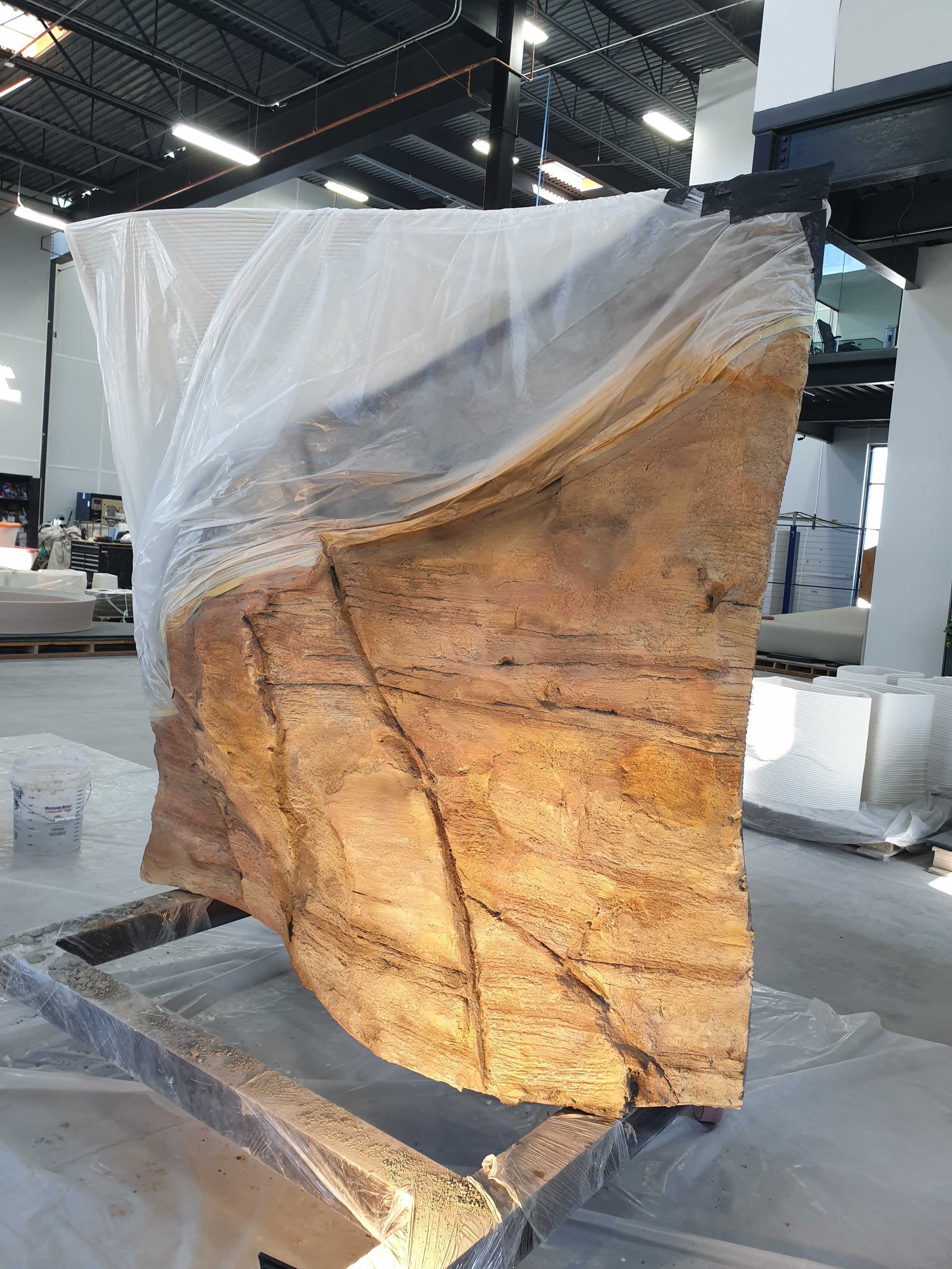

To develop this theory, Pikus has worked closely with some of the top rockwork artists in the United States. Across the nation, brilliant minds have worked to design and implement 3D-printed rockwork in multiple locations. The immense level of research and effort that went into Pikus Rockwork has proven that 3D printing is the future of the industry. To celebrate, Pikus has developed an in-house rockwork statement piece in partnership with one of the largest designers of statement water features in the USA.

Pikus has truly tested and retested the materials, attachments, and printing methods that are needed to begin implementing printed rockwork features. We are so excited to bring this technology to locations across the globe as a stable and economical alternative to the labor-intensive chip and tab methods. For more information on Pikus Rockwork pieces, take a look at our product data sheets or reach out to Pikus directly at create@pikus3d.com.